ZAHORANSKY AG

Produce toothbrushes with plastic anchors on the Z.ORCA and CUBE machines

Small machine adaptation, big impact for the environment

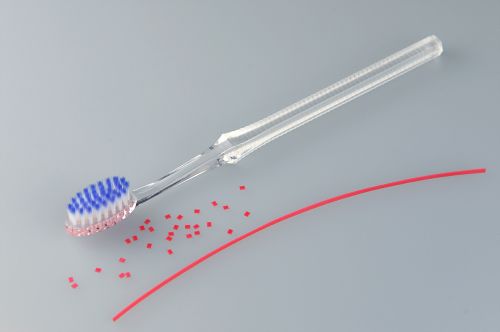

From now on, toothbrushes can also be produced on the proven ZAHORANSKY Z.ORCA and CUBE machines without the use of metal anchors. Instead, plastic anchors can be used. Existing machinery or new acquisitions only need to be minimally adapted for this. ZAHORANSKY thus offers its customers the opportunity to further develop their product range in line with current consumer wishes and market trends easily without high investments. In the oral care sector, consumers are also increasingly making their purchasing decisions based on the eco-balance of the products – pure plastic toothbrushes perform better than conventional toothbrushes with a metal anchor. For example, fully recyclable toothbrushes or models where only the brush head needs to be replaced are in vogue. ZAHORANSKY's aim is to provide manufacturers with technologies with which product innovations can be realized in terms of sustainability. With this aspiration, the EDGE was launched in 2024 – a machine that enables the production of anchorless mono-material toothbrushes with maximum design freedom thanks to an innovative process.

More sustainability, more efficiency, familiar performance

To be able to produce the so-called mono-material toothbrushes on the ZAHORANSKY Z.ORCA and CUBE machines, only the corresponding assembly needs to be adapted. Instead of the previously used metal anchors, the filaments in the brush head are then fixed with plastic anchors. As the toothbrush body, filaments and anchors are made of plastic, toothbrushes that are no longer used can be easily and completely recycled - a plus for the eco-balance. At the same time, the machines score points with the usual ZAHORANSKY safety and product quality. With a tufting speed of up to 1,200 bundles/min, the same performance is possible as when using metal anchors. The use of plastic anchors can also be interesting in terms of more economical production, as the material price is lower than for the metal version.

Further information:

ZAHORANSKY AG

Andreas Ehmann, Product Marketing

Anton-Zahoransky-Straße 1

79674 Todtnau-Geschwend

Tel.: +49 (0) 7671 997-0

E-Mail: info@zahoransky.com

www.zahoransky.com

Press and public relations:

Press'n'Relations GmbH

Nataša Forstner und Christoph Buck

Magirusstr. 33, 89077 Ulm

Tel. +49 731 146 156-77 bzw. -74

E-Mail: nfo@press-n-relations.de und cb@press-n-relations.de

www.press-n-relations.de

Background information ZAHORANSKY

ZAHORANSKY AG is known for cutting-edge technology in machine engineering and mold making for over 120 years and is today an internationally active technology provider which is 100% family owned. Based on decades of experience combined with foresight and a culture of innovation, ZAHORANSKY is a full-service provider and technology partner for companies in the brush industry, medical technology and other sectors. Market-leading manufacturers of oral care and cosmetic products, producers of household and industrial brushes as well as pharmaceutical companies worldwide rely on the comprehensive consulting, development and service expertise of ZAHORANSKY.

One of the company‘s proven strengths: on request, ZAHORANSKY provides customers with complete solutions from a single source for the manufacture of complex plastic, hybrid and glass replacement products. This includes injection molds, upstream and downstream automation solutions and quality control as well as the integration of injection molding machines and other system components for turnkey, fully automated production lines. About 750 people are employed at our headquarters in Germany and the sites in Spain, China, India, Japan, Brazil and the USA.