ZAHORANSKY AG

ZAHORANSKY at Fakuma 2023: Producing plastic syringes with screw threads cost-efficiently and safely

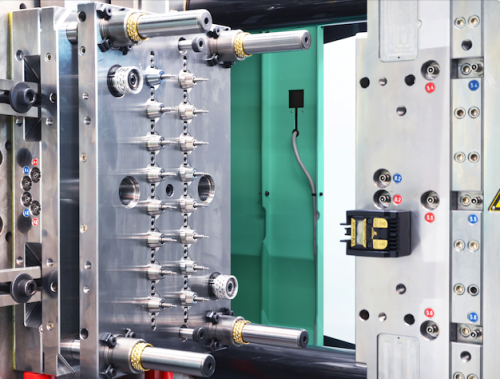

Manufacturing luer-lock from plastic instead of glass - with the ZAHORANSKY Z.SONIC

Even a good 150 years after their invention, the standardized luer connection systems for infusions and injections are still frequently made of glass. At Fakuma 2023 (Hall A2, Stand A2-2309), ZAHORANSKY will be exhibiting the associated Z.SONIC 16 luer-lock syringe injection mold from the PRIMA Z syringe production system, which can be used to manufacture luer-locks from plastic instead of glass. The advantages of the plastic versions are clear: plastic products are significantly more robust and easier to clean, both in handling and storage, compared to their glass counterparts. In addition, syringes made of plastic impress with their pH-neutral surface, a significantly lower heavy metal content, and greater freedom in product design. This results in increased shelf life for highly sensitive medications.

Safe and cost-effective manufacturing

The PRIMA Z production line makes it possible to produce plastic syringes with screw threads - the so-called Luer-Lock - extremely cost-efficiently and safely. Disposable needles, for example, can be screwed on easily afterwards and do not have to be injected during production. Syringes with volumes between 0.5 and 10 ml can be produced as standard, but special sizes of up to 50 ml are also possible. The material can also be varied: ZAHORANSKY injection molds easily process various technical polymers such as COC or COP. Based on customer-specific product designs, a cycle time of 15 to 17 seconds can be achieved on the production lines using the no-human-touch process. In the 16-cavity injection mold version, the Z.SONIC mold is thus capable of producing up to 3,840 parts per hour.

Further information:

ZAHORANSKY AG

Robert Dous, Managing Director of ZAHORANSKY Automation & Molds

and Chief Sales Officer of ZAHORANSKY GROUP

Anton-Zahoransky-Strasse 1

79674 Todtnau-Geschwend

Phone: +49 (0) 7671 997-0

Email: robert.dous@zahoransky.com

www.zahoransky.com

Press and public relations:

Press'n'Relations GmbH

Nataša Forstner

Magirusstr. 33, 89077 Ulm

Phone: +49 (0) 731 96287-17

Email: nfo@press-n-relations.de,

www.press-n-relations.de

Background information

The name ZAHORANSKY has stood for reliability, precision, and sophisticated technology since 1902. The foundation for this was laid by Anton Zahoransky in his small workshop in Todtnau, where he manufactured the first devices and machines for automated brush production.

Thanks to the experience and expertise gained since then, ZAHORANSKY is now a full-range supplier and technology partner for companies in the brush industry, medical technology, and other sectors. With injection molds, mechanical engineering, automation technology, and packaging systems, ZAHORANSKY can provide comprehensive services for individual requirements. Approximately 900 employees, including 70 trainees, work to achieve this every day at ten locations in Germany, Spain, China, India, Japan, Brazil, and the United States.

ZAHORANSKY’s multi-system solutions cover the entire process chain: from integrating packaging technology and handling, to programming and robotics in the manufacture of fully automated production and assembly systems. ZAHORANSKY's technologies and services are widely used in the following industries: household and industrial brushes, oral care, medical technology, cosmetics, consumer goods, and packaging.