Wieland Werke AG

Extended solarclean product family: Wieland will be presenting solar thermal copper tubes at Intersolar 2012 New: solarclean_plus with optimised bending properties

Intersolar, trade fair in Munich, 13 to 15 June 2012, Hall B1, Stand 690

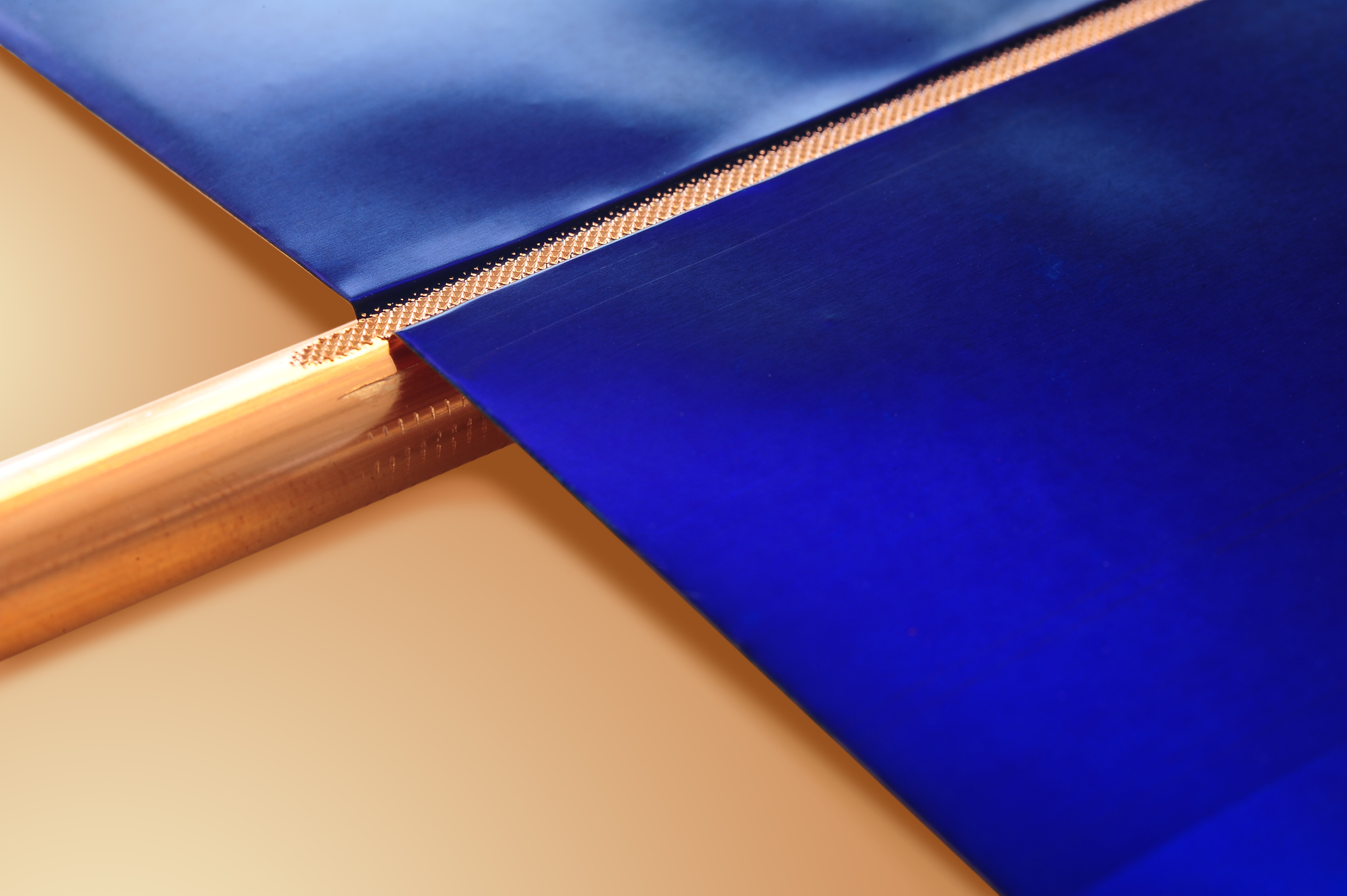

At Intersolar 2012, Wieland-Werke AG, Ulm, will be presenting the wide range of Wieland Thermal Solutions for solar thermal applications, heat exchangers and finned tubes. In the solar thermal segment, Wieland will be exhibiting the entire solarclean copper-tube product family. In addition to enhanced tube products, the company will for the first time be presenting the new solarclean_plus copper tube with optimised bending properties. The new development is particularly suitable for collectors with complex meander tubes. Like all Wieland tubes in solarclean quality, the new product is characterised by an ultra-clean surface. Due to their special surface quality solarclean tubes increase productivity in the manufacture of solar heat absorbers. In addition, Wieland will be presenting the WICOATEC coating as well as the other finned tubes of its product range. Inner- and outer-grooved tubes with the largest possible surface area represent an energy-efficient solution for heat exchangers in solar tanks and gas-fired boilers. Wieland tubes are made of the natural and 100% recyclable copper – the metal with the highest thermal conductivity after silver. With regard to finned tubes, Wieland will be showcasing a tube-in-tube solution with GEWA-safe which is suitable for the heating of drinking water using heat pumps. The GEWA-safe technology takes into account most of the European safety regulations. In many European countries, these safety regulations specify double-walled tubes in order to prevent drinking water from mixing with refrigerant in case of leakage.

solarclean product family

Compared to conventional tubes, classical solarclean copper tubes permit higher welding speeds. This makes additional cleaning during production unnecessary and results in significant cost reductions. Besides solarclean_classic, which is already established in the market, Wieland offers a number of other solarclean qualities: solarclean_hp has been developed by Wieland for the manufacture of heat pipes in vacuum tube collectors. The particularly clean outer and inner surface not only ensures improved welding and soldering properties but also a constant level of efficiency of the tube collectors. Copper tubes in the new solarclean_plus quality are particularly suitable for the bending of meander tubes for collectors. solarclean_eco is an economical product variant that is particularly suitable for laser welding. solarclean copper tubes are normally supplied hard as drawn in level-wound coils.

Safety tubes for heat exchangers

The proven finned-tube heat exchangers in copper for the heating of solar water tanks are another highlight at Intersolar. These long-life heat exchangers from Wieland can also be subsequently installed in existing systems. They are also available as safety heat exchangers in a special product version with a double-tube system. GEWA-safe safety tubes are based on a tube-in-tube solution. Channels between inner and outer tube make easy control of the leakage gap possible. GEWA-safe tubes allow system operators in many European countries to meet the respective drinking-water standards, for example according to DIN EN 1717 for heat-pump systems. Easy leakage detection and the double-wall design ensure optimum protection against water contamination by oil contained in the refrigerant.

Strong and very thin: WICOATEC coating results in longer life

At Intersolar, Wieland will be presenting the innovative WICOATEC coating in the field of heating engineering. Because of its resistance to acids, alkaline solutions and water as well as temperatures of up to 400 °C, this silicon-oxide coating has been specially developed for condensing boilers. The high-quality surface coating is extremely uniform and completely covers all types of structures. As a result, aluminium components can also be effectively protected against acid corrosion. Another special characteristic of WICOATEC is resistance to undermining and delamination. Besides aluminium, metals such as copper, copper-nickel or stainless steel can be coated as well. So there are practically no limits to the applications of WICOATEC in terms of corrosion protection and temperature resistance.

Copper: durable, reliable, 100 % recyclable

For solar thermal applications copper remains the material of choice. It is the metal with the highest thermal conductivity after silver and is particularly suitable for thermal engineering applications. The red metal not only exhibits outstanding physical properties but is also characterised by high corrosion resistance, excellent processing properties and long life. At a current material value of 8 to 9 euros for the absorber tube per square metre collector surface, copper can still be used economically despite the relatively high material prices – particularly in view of the fact that a reduction of wall thickness results in savings potential. Moreover, in many solar thermal applications copper cannot practically be substituted.

Further information:

Wieland-Werke AG

Karin Maier, Public Relations

Graf-Arco-Straße 36 - 89079 Ulm, Germany

Tel. 0049 731-944-2663

Fax 0049 731-944-42663

karin.maier@wieland.de

www.wieland.de

Public relations:

Press’n’Relations GmbH

Bruno Lukas

Magirusstraße 33 - 89077 Ulm, Germany

Tel. 0049 731-9628717

Fax 0049 731-9628797

blu@press-n-relations.de

www.press-n-relations.de

The Wieland Group is one of the world’s leading manufacturers of semi-finished and special products in copper and copper alloys such as strip, sheet, tube, rod, wire and sections as well as sliding elements, finned tubes and heat exchangers. The products made of more than 100 different copper alloys are mainly used in the electrical and electronic industries. Other important sectors are the construction, automotive, air-conditioning and refrigeration industries as well as heating engineering and machine and apparatus construction. In cooperation with its customers Wieland develops specific solutions for industrial applications. The Wieland Group has more than 30 manufacturing companies, slitting centres and trading companies in Europe, Asia, South Africa and the USA. Wieland-Werke AG operates four plants in Ulm, Velbert-Langenberg, Villingen-Schwenningen and Vöhringen. Wieland’s branded copper tubes for domestic applications are manufactured in Germany at the Vöhringen (Bavaria) plant. The company’s R&D as well as production and sales are certified according to DIN EN ISO 9001. Moreover, Wieland has an accredited test and certification laboratory. The plants in Germany are certified according to the international environmental standard DIN EN ISO 14001. The largest production site in Vöhringen is validated according to the European environmental standard EMAS. The Wieland Group achieved a turnover of 3,287 million euros in the fiscal year 2010/2011 with sales quantities of 475,000 tons. The global workforce of the Wieland Group is approx. 6,500 strong of which over 4,000 are employed in Germany.