Fast selection now possible of energy-saving air-handling units / GEA chillers satisfy Eurovent class A

GEA design software Lplus assigns models in the GEA CAIRplus range to the new Eurovent energy-efficiency classes / GEA chillers are now also available in high-efficiency versions

- - - - - - - - Press release 1 - - - - - - - -

GEA design software Lplus assigns models in the GEA CAIRplus range to the new Eurovent energy-efficiency classes

Fast selection now possible of energy-saving air-handling units

GEA Air Treatment GmbH, of Herne, Germany, in its design software Lplus is now the very first company to assign air-handling units to the new Eurovent energy-efficiency classes A to F. With this program Lplus, customers can now not only individually configure the models in the GEA CAIRplus range, but can also check them for energy-efficiency according to the latest criteria. Life-cycle cost calculations complete the selection process. These calculations allow conclusions on the cost-effectiveness of the models under planned conditions of use.

Before ordering of actual systems, Lplus provides planners and decision-makers with reliable data on how energy-efficient the configured model is. The program assigns a model being considered to the new Eurovent efficiency classes on the basis of 3 criteria: the air speed in the internal cross-section, the heat-recovery coefficient and pressure drop of the heat-recovery units, as well as the power consumed by the fan. Eurovent classification takes place in accordance with the new procedure, the new features of which include significantly more precise gradation than earlier (see text in box below).

If the configured model does not satisfy the requirement of the required efficiency class, the user enjoys various modification options: e.g., enlargement of the model cross-section, selection of a different energy-recuperation unit, or use of a more efficient fan. The current version of Lplus, 5.37, allows selection, for example, of EFF-1 motors that have efficiencies up to 10% greater than EFF2 drives. One of the benefits of the ECOPLAT-TWIN double-plate heat exchanger is its high heat-recovery coefficient and, in turn, the good Eurovent classification that it enables. Most recently, moreover, the plate spacing that can now be selected for ECOPLAT double-plate heat exchangers enables greater design leeway. Proper selection of plate spacing ("S”) allows good heat recovery – as well as greater pressure drops, which require the use of efficient fans. "M” stands for mean values, and "L” is the optimal solution when low pressure drops are more important than a high heat-recovery coefficient.

((Text box))

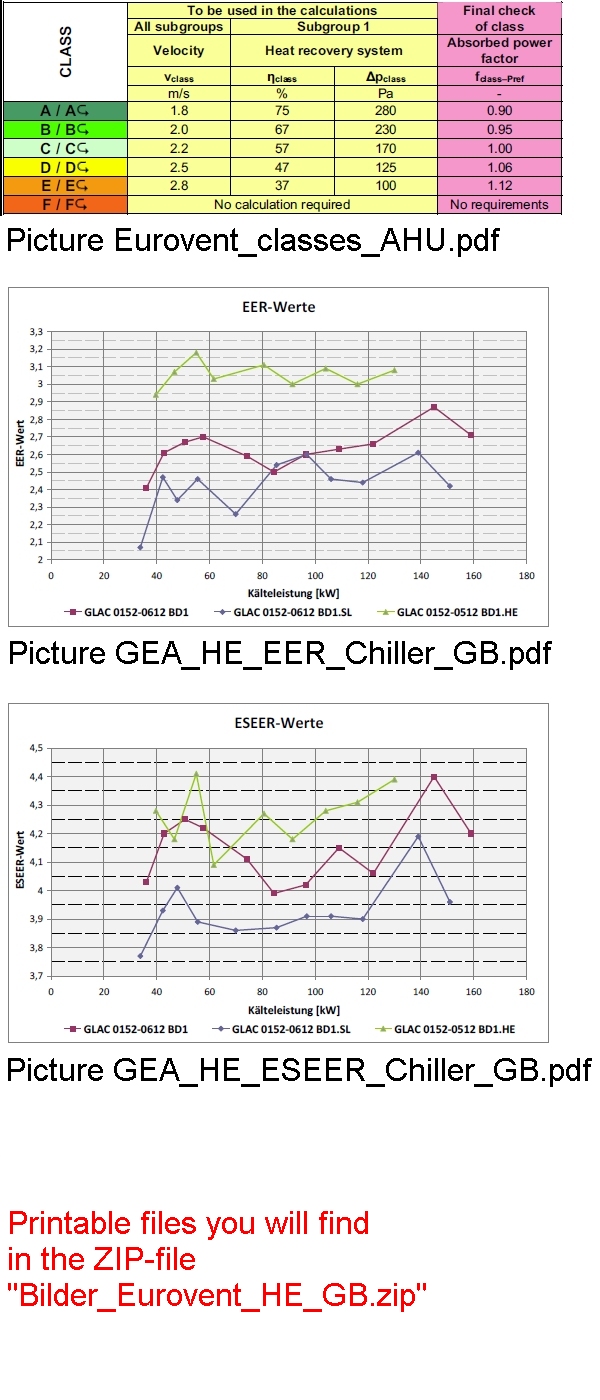

New energy-efficient classes in accordance with Eurovent – these have now changed

The new Eurovent energy-efficiency classes A to F, presented this year at the specialist trade show ISH, replace the old scale of A to C. Calculation of the classes is now based on the revised version of DIN EN 13053 (not yet published). Also new are the compensation options between the criteria. Now, not all limit values of an efficiency class must be simultaneously fulfilled to achieve a certain class. For example, a more efficient fan or an enhanced heat recovery can compensate for increased air speed in the model. An additional new requirement is that all models in classes A to E must be equipped with heat recovery. Class F places no requirements on the energy efficiency of the models, but verifies conformity with the other tests in the Eurovent program (e.g., model box test and output tests).

Picture Eurovent_classes_AHU.pdf - Source: Eurovent:

The new Eurovent energy-efficiency classes for air handling units are based on the modified version of DIN EN 13053 (not yet published).

- - - - - - - - Press release 2 - - - - - - - -

GEA chillers satisfy Eurovent class A

GEA chillers are now also available in high-efficiency versions

Beginning immediately, GEA Air Treatment GmbH, of Herne, Germany, now also offers air-cooled chillers in series GLAC 0152-0612 BD1 as high-efficiency models (HE). As a result, these HE units – which offer approx. 40 to 130 kW of rated cooling capacity, depending on the model – satisfy the strict requirements for Eurovent class A. In addition to these models with top energy efficiency for outdoor installation, the chillers of this series continue to remain available as standard machines and in an extra-quiet SL version.

If the customer is looking for high cooling capacity with a minimum of energy consumption, GEA chillers in the new HE version represent the ideal solution. After all, the new HE units achieve EER1) values up to 3.18 under full-load conditions. The ESEER2) ratings (which also take into account the partial-load cases that frequently occur in comfort climate control) even reach values up to 4.4. These new chillers have already been integrated into Lplus, the GEA design software.

HE versions for other chiller series are planned to be available soon. These developments mean that GEA Air Treatment is once again implementing its slogan "Air Eco2nomy”: after all, reduction in consumption of resources goes hand in hand with more careful interaction with our environment, and with reduction in operating costs.

1) EER = Energy Efficiency Ratio

2) ESEER = European Seasonal Energy Efficiency Ratio

The following plots show the ratios EER and ESEER for several models in the series GLAC 0152-0612 BD1: for the new HE version (green), the standard models (red), and models in the especially quiet SL version (blue).

Picture GEA_HE_EER_Chiller_GB.pdf:

For units that operate under full load almost the entire year, an EER ratio as high is possible is especially important. These conditions often occur in production facilities and in computer centers.

Picture GEA_HE_ESEER_Chiller_GB.pdf:

For comfort climate control, we recommend using the ratio ESEER as a criterion, since it takes greater account of the partial-load conditions that frequently prevail.

---------------------------------------------

Press Relations and Public Affairs:

GEA Air Treatment GmbH – Ms. Annette Wille

Suedstrasse 48 - 44625 Herne, Germany

Tel.: +49 (0)2325 468 206 - Fax: +49 (0)2325 468 401

www.gea-airtreatment.com

Press’n’Relations II GmbH - Ralf Dunker

Guntherstrasse 19 - 80639 Munich, Germany

Tel.: +49 (0)89 179 992 75 - Fax: +49 (0)89 179 992 89

The text and printable pictures are available in the DOC-/ZIP-files below