From Artistic Lock Making to Machine and Valve Building

Family Company Lohse Celebrates its 100-Year Anniversary

High-tech products "Made in Germany” for paper production, waste management and air technology

Everything began exactly one century ago when Georg Bauder founded a building and artistic locksmith workshop in 1908. In so doing, the artistic craftsman laid the foundations for the traditional operation Lohse, which celebrates its 100-year anniversary in September – an industrial success story. Over the course of the decades, two modern and highly specialised industrial companies developed from the Heidenheim factory, which are successful worldwide in machine building and in the production of valves. The two Lohse companies, Maschinenbau Lohse GmbH and Martin Lohse GmbH, with their 164 employees and high-tech factories work mainly with paper manufacturers, waste management companies and air technology specialists. "Know-how of metal processing is the basis of our success”, stresses Martin Lohse, managing director and son of the company’s namesake Martin Lohse senior. "From the start, this knowledge base has been continually developed. By transferring know-how to various new areas of application our traditional operation has been able to master more and more business areas over time.

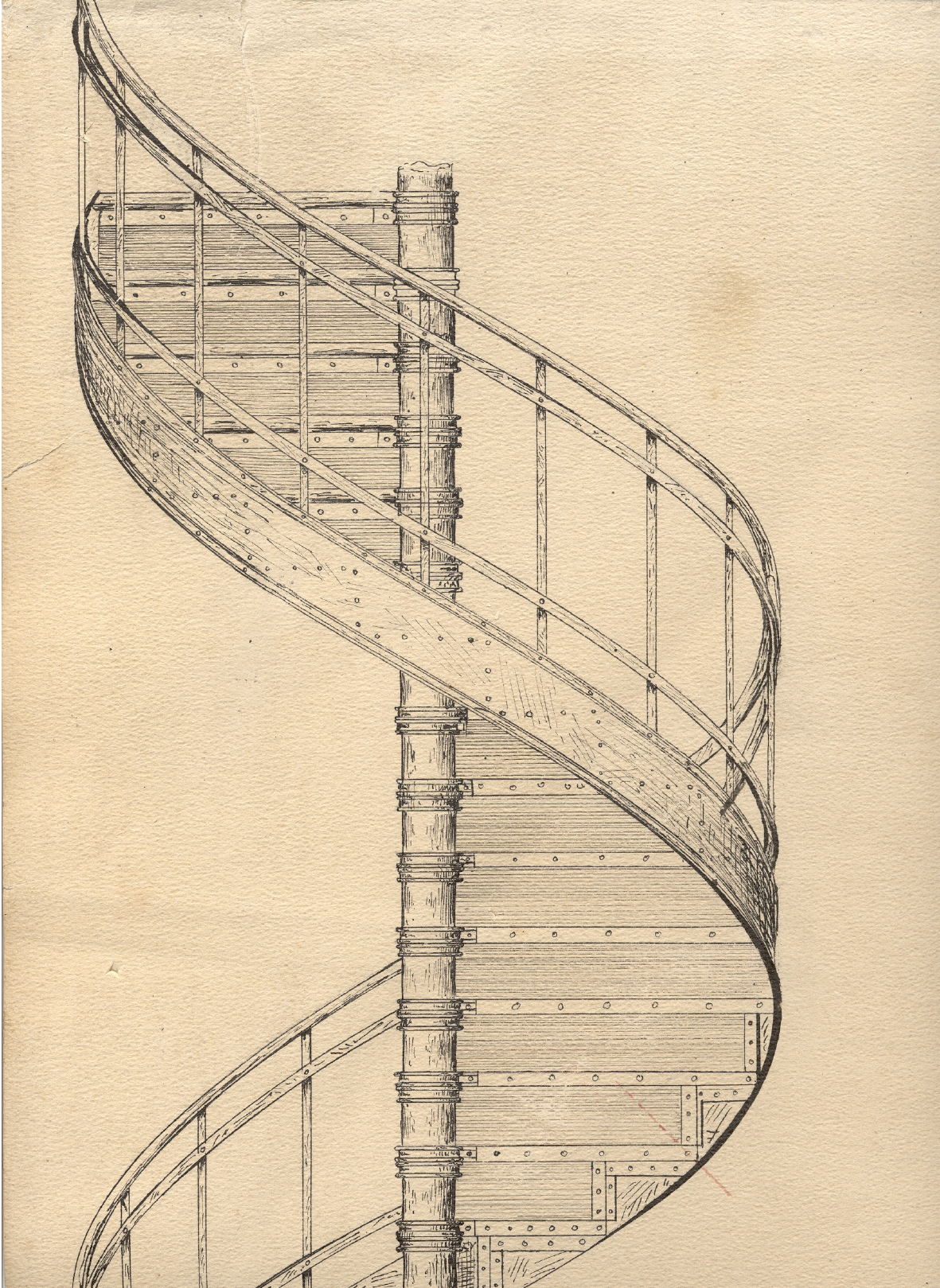

The starting point for the 100-year company history is Georg Bauder's artistic smith workshop in Heidenheim. Work there included the creation of wrought-iron windows, gates, folding grilles and containers, but was predominantly focussed on the construction of spiral staircases. Bauder’s artistic workshop "Georg Bauder” occupied a gap in the market in stair building and he was able to expand his business dramatically; by 1912 he was already employing 60 people. In addition to spiral staircase series production the company produced components for significant building works, for example the iron gates and interlocking grates for the Hochbrücke bridge at Rendsburg, which spans the Kaiser Wilhelm canal.

In 1927, Martin Lohse joined the company. After the death of the company’s founder, Georg Bauder, in 1928 Martin Lohse senior became managing director. On his marriage to Ella Bauder, the founder’s daughter, Lohse finally took over the operation in 1932, which continued to operate under the name "Georg Bauder, Inh. Martin Lohse” until 1955. After a difficult few years during the world economic crisis, Martin Lohse expanded business and, in the war years from 1940 to 1945, the company completed an array of orders for the civil defence. For instance, the company made air raid protection doors, which can still be seen today in many houses in Heidenheim and its surroundings.

The Pulper Brings the Breakthrough into Paper Technology

The company’s materials know-how and great expertise in metal processing led to an order in 1949 that marked a significant milestone: The production of the first pulper for the Heidenheim company Voith. "The manufacture of this part, which plays a central role in paper production, gave our company a way into the growing market for paper technology”, explains managing director Martin Lohse. At the same time, the manufacture of the pulper formed the knowledge base for entering waste management, which followed in the middle of the 1980s. In the 195os and 1960s the company continually expanded its product portfolio and supplied well-known paper and paper machine manufacturers with central components for material preparation, the preliminary stage of paper production - including vats, containers, vibration sorters, flotation machines and feeders.

Valve Manufacture and Opening the Oggenhausen Site

Production of the first knife gate valve for the paper industry in 1959 was the foundation for the manufacture of valves. Whilst construction of machines and plants is realised as piece production as a rule, valves are produced in series and this led to the first separation of the valve and container production areas. In 1963, container production was moved to the newly erected purpose-built site in Heidenheim-Oggenhausen.

Diversification: nuclear technology, ventilators, wind tunnels

After the death of Martin Lohse senior the company was renamed as Martin Lohse GmbH & Co. KG Maschinen- und Apparatebau in 1972. Management now took on two long-term staff, son-in-law Klaus Warnke, responsible for production and purchasing, and Dietrich Gräßer, responsible for sales. In addition to continual and successful expansion of the machine and valve production, in the 1970s new business fields were added, which developed on the basis of the well-founded materials knowledge. The company, which now had well over 120 staff, became involved in nuclear power station technology from 1973 and developed products including heat exchangers, sampling and decontamination plants. "The company is still profiting today from the know-how that our staff have acquired in this field. It allows us to develop technically very complex solutions as well”, explains managing director Dietmar Warnke, son of Klaus Warnke and great-grandchild of the company founder; the fourth generation in the family firm. Parallel to the entry into power station technology, Lohse focussed on production of cooler housings and ventilators that had been underway for many years, by concluding a licence agreement with Voith Getriebe KG. Thus, the company is in a position to set-up its own sales of ventilators for industrial applications. Construction of large axial fans for tunnels, mine exhausts and wind tunnels emerged from this business field in close cooperation with Howden. The applications of these wind tunnels include optimising the aerodynamics and acoustics of cars and fast trains, but also racing cars. Famous names like Daimler, BMW and Renault are end customers, as well as McLaren-Mercedes, Williams and other prominent racing teams in the area of high-speed tunnels.

Waste Management as a New Business Field

From 1985, Lohse accessed another lucrative business field with its extensive know-how from the paper industry: waste management. The processes in this field are based on similar principles and, therefore, through this research and development into the treatment and utilisation of biological waste Lohse has developed into one of the technology leaders in the market - in Germany and worldwide. In 2000, Lohse achieved the last significant milestone to date in the company's development: With the separation of the valve and machine building departments the manufacturer has undertaken n important reorganisation of internal processes. The result is Martin Lohse GmbH, which is responsible for the manufacture of valves, and Maschinenbau Lohse GmbH, responsible for the manufacture of machines, plants and apparatus.

Photos:

1. View of the first workshop (1909) - (1909_Gruenderwerkstatt.jpg)

2. Stair construction – the main product in the early years - (1912_WendeltreppeZeichung.jpg)

3. Construction of the pulper facilitates entry into paper technology (1955_Stoffloeser.jpg)

4. Production of the first feeder - (1961_erste_Schieber.jpg)

5. Company founder Georg Bauder - (Bauder_Georg.jpg)

6. Martin Lohse senior (1971_MartinLohseSen.jpg)

7. Martin Lohse, Dietrich Gräßer, Klaus Warnke

(from left to right) - (1983_Geschaeftsfuehrung_Lohse_Graesse_Warnke.jpg)

8. Martin Lohse - current managing director (Lohse_Martin_Geschaeftsfuehrer.jpg

9. Dietmar Warnke - current managing director (Warnke_Dietmar_Geschaefsführer.jpg)

10. The Lohse company site at Heidenheim-Oggenhausen (2000_Firmenareal.jpg)

Other information:

Martin Lohse GmbH

Christine Cordes

|

Unteres Paradies 63 – 89522 Heidenheim-Oggenhausen Tel. +49 7321 755 55 – Fax: +49 7321 755 97 christine.cordes@lohse-gmbh.de - www.lohse-gmbh.de

|

|

|

Martin Lohse Managing Director

Unteres Paradies 63 – 89522 Heidenheim-Oggenhausen Tel. +49 7321 755 0 – Fax: +49 7321 755 99 martin.lohse@lohse-gmbh.de - www.lohse-gmbh.de

|

|

|

(FH) Dietmar Warnke Managing Director

Unteres Paradies 63 – 89522 Heidenheim-Oggenhausen Tel. +49 7321 755 0 – Fax: +49 7321 755 99 dietmar.warnke@lohse-gmbh.de - www.lohse-gmbh.de |

Press and Public Relations:

|

Bruno Lukas

Magirusstr. 33 - D-89077 Ulm Tel.: +49 731 962 87 17 - Fax: +49 731 / 962 87 97 blu@press-n-relations.de - www.press-n-relations.de

|