Wieland Werke AG

Metal meets plastics: Wieland presents copper alloys and semi-finished products at the new hybridica trade fair

Hybrid components: international trade fair for the development and manufacture of metal-plastics components

hybridica trade fair Munich, 11 – 14 November 2008, hall C2, stand 223

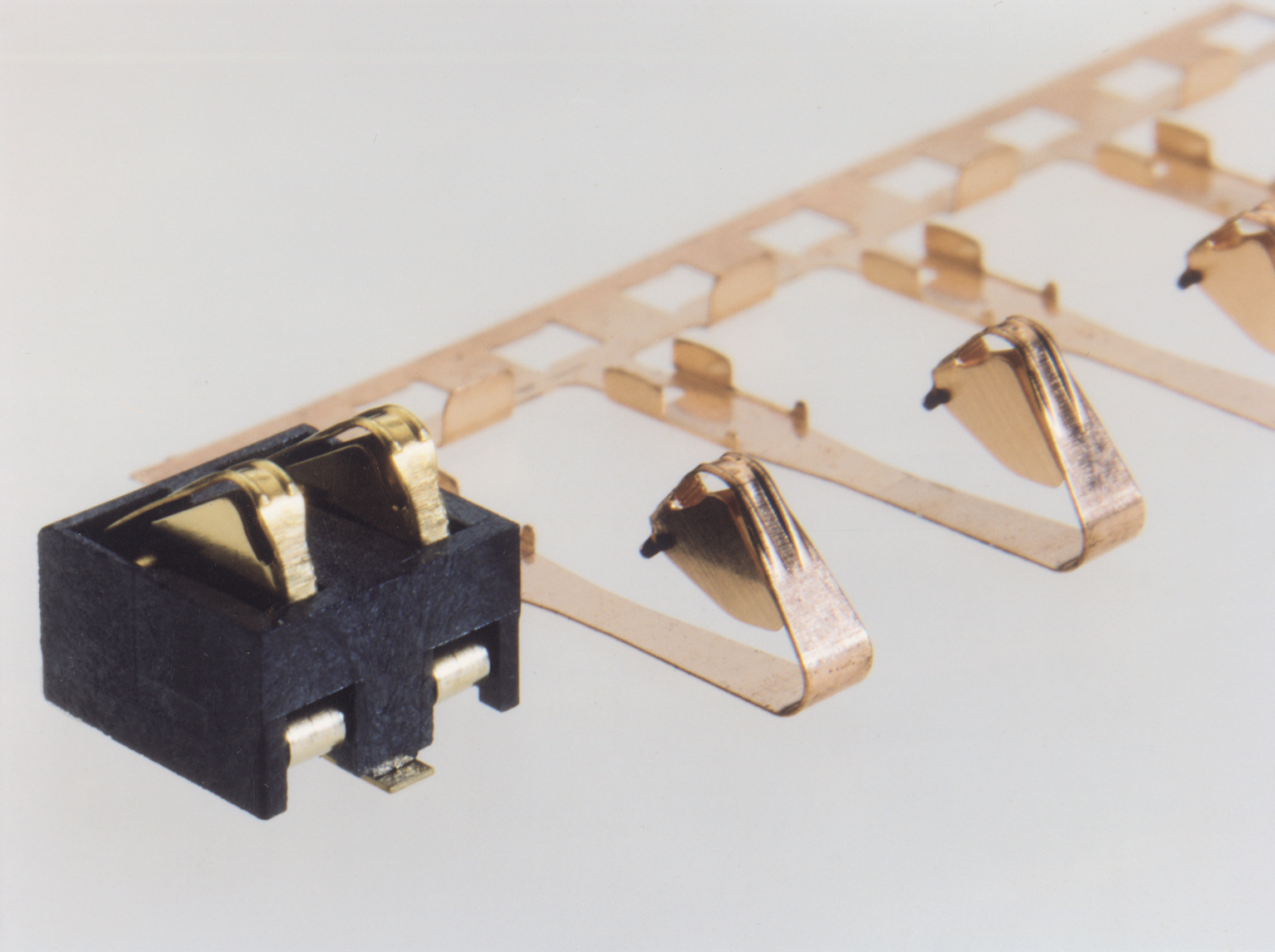

Premiere in Munich: In the middle of November 2008, hybridica – the largest international trade fair and presentation platform for hybrid components – opened its doors for the first time. The focus was on the development and manufacture of metal-plastic components. As one of the world’s leading manufacturers of copper and copper-alloy semi-finished products Wieland exhibited a wide range of strip and wire for the electronic and electrical industry. Hybrid components are becoming more important for manufacturers of semi-finished products such as Wieland as a large proportion of metal semi-finished products is joined directly or indirectly with plastic. Combined and integrated production processes play an increasingly important role. Wieland participated in hybridica and also utilized the synergy potential of electronica – the international trade fair for electronic components, systems and applications – taking place at the same time at the New Munich Trade Fair Center. Exhibition highlights at hybridica were the new, fine-grained SUPRALLOY bronzes, a number of different types of special strip and wire as well as Wieland’s know-how in surface finishing. The company targeted designers of electrical, electronic and electromechanical components, in particular decision makers who are in charge of material selection and process engineering for hybrid components.

Wieland presented its fine-grained SUPRALLOY bronzes characterized by a much finer microstructure than conventional bronzes. With a grain size of maximum 3 µm compared to 8 µm of standard bronzes, SUPRALLOY has a substantially higher mechanical strength in conjunction with very good bending properties. Its electrical conductivity is identical with that of standard bronzes. The SUPRALLOY bronzes B14, B16 and B18 have tin contents of 4, 6 and 8 percent and are supplied in several tempers each. SUPRALLOY is available in strip thicknesses between 0.08 mm and 0.35 mm and outstandingly suitable for high-tech low-cost applications in the automotive and telecommunications industries. Applications with Wieland SUPRALLOY bronzes can be utilized under certain circumstances which would otherwise be restricted to high-performance alloys.

Surface finishing know-how

One of the exhibition highlights was the presentation of Wieland’s know-how in surface finishing. The quality of components depends next to their mechanical characteristics largely on their surface properties. Wieland applies special plating techniques to meet the high quality standards required of metal strip when utilized as basic material for electrical and electronic components.The company presented high-quality surfaces for leadframes for the manufacture of integrated circuits. Other products exhibited by Wieland were contour-milled strip for power electronics components, hot-dip tinned and tin electroplated strip as well as hot-dip tinned flat wire and electronic wire.

Hot-dip tinning as corrosion protection – wire and strip

Wieland is Europe’s leading manufacturer of hot-dip tinned strip in copper and copper alloys. Hot-dip tinning is a low-cost technique preventing the formation of oxide on electromechanical components and consequently ensuring that contact resistance is not adversely affected. At the hybridica fair, Wieland presented different types of tin coatings for special customer requirements: the pure tin coating SnPUR, the tempered pure tin coating SnTEM, and SnTOP, a tin-silver coating which exhibits low contact resistance with high wear and temperature resistance. A new Wieland product is flat wire made of high-conductivity pure copper which is hot-dip tinned for higher resistance to whisker formation in electrical contacts. Hot-dip tinning ensures perfect adhesion of the tin coating to the base metal.

Wieland also manufactures wire for electronic applications. Special alloying additions and heat treatments make the materials suitable for high currents as well as resistant to fatigue, high temperatures and stress relaxation. Wieland-K55, K65, K80 and K88 are used for connector pins, coil springs, fatigue-resistant stranded wire and high-strength enamelled wire.

Further information:

Wieland-Werke AG

Karin Maier, Public Relations

Graf-Arco-Straße 36 – 89079 Ulm, Germany

Tel. 0049 731-944-2663 – fax 944-42663

karin.maier@wieland.de, www.wieland.de

Wieland-Werke AG

Dr. Gerhard Schüz

Head of Technical and Strategic Marketing, Rolled Products

Graf-Arco-Straße 36 – 89079 Ulm, Germany

Tel. 0049 731-944-2007 – fax 944-4129

gerhard.schuez@wieland.de

Wieland-Werke AG

Dr. Robert Zauter

Product Management and Marketing

Extruded and Drawn Products

Graf-Arco-Straße 36 – 89079 Ulm, Germany

Tel. 0049 731-944-2277 – fax 944-4550

robert.zauter@wieland.de

Public Relations:

Press’n’Relations GmbH

Bruno Lukas

Magirusstraße 33 - 89077 Ulm, Germany

Tel. 0049 731-9628717 – fax 9628797

blu@press-n-relations.de, www.press-n-relations-de

The Wieland Group is one of the world’s leading manufacturers of semi-finished and special products in copper and copper alloys such as strip, sheet, tube, rod, wire and sections as well as sliding elements, finned tubes and heat exchangers. Wieland supplies customers in numerous markets. The products made of more than 100 different copper alloys are mainly used in the electrical and electronic industries. Other important sectors are the construction, automotive, air-conditioning and refrigeration industries as well as heating technology and mechanical and plant engineering. In cooperation with its customers Wieland develops specific solutions for industrial applications. The Wieland Group has more than 30 production sites, slitting centers and trading companies in Europe, China, Singapore, South Africa and the United States. Wieland-Werke AG has four plants in Ulm, Velbert-Langenberg, Villingen-Schwenningen and Vöhringen. Wieland’s R&D as well as production and sales are certified according to DIN EN ISO 9001:2000-12. In addition, the company has an accredited test and certification laboratory.

Wieland-Werke AG achieved a turnover of 2,255 million euros in the fiscal year 2006/2007. The turnover of the Wieland Group was 2,908 million euros with an export share of 67 percent. The global workforce of the Wieland Group is approx. 6,500 strong of which 4,000 are employed in Germany.

Rod, wire, tube and sections from Wieland are used wherever the highest technical requirements have to be met. Wieland manufactures these semi-finished products in various dimensions and alloys such as brass, bronze, nickel silver and high-performance alloys. With ECOBRASS and ECOCAST the company has developed two special brasses which are lead-free and at the same time have good processing properties. Wieland materials and semi-finished products are suitable for a wide range of applications, for example, in the electronics, automotive as well as IT and infrastructure sectors.