Wieland Werke AG

Presskit ISH 2011 - Wieland Werke AG: System solutions for renovation, materials for sanitary applications, piping for refrigeration and air-conditioning

ISH, Frankfurt Fair, 15th to 19th March, 2011, Hall 6.0, Stand B40 and Stand B44

Please find attached the ISH Press releases in Word format as well as the photos.

- Press release ISH 2011

- Press release cuprotherm

- Press release K65

- Company portrait Wieland-Werke AG.

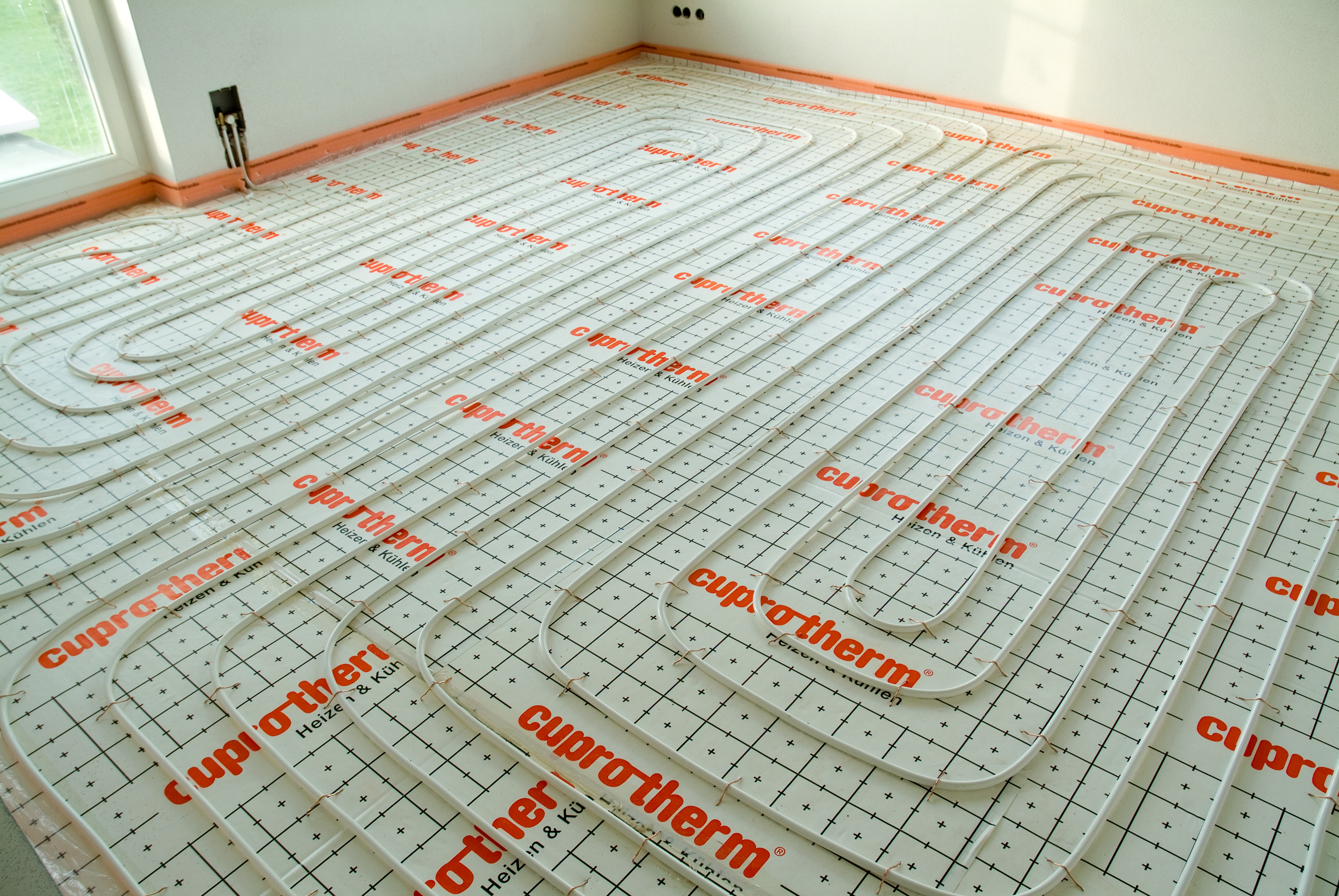

At the ISH 2011, the Ulm-based Wieland Werke AG is presenting a wide selection of new and proven building-service solutions based on the natural material copper. In the area of panel temperature control, the emphasis of the Wieland presentation is on the new cuprotherm system variants for renovation and dry-wall construction. With cupronova, Wieland exhibits an easy-to-install wall heating system specially for construction work in existing buildings. For the cuprotherm CTX system, Wieland presents a series of new components for drinking-water applications and radiator connections. The focus in the drinking-water installation segment at the fair is on the SANCO brand copper-pipe products, which have proved their worth for decades, and which Wieland offers in additional sizes with reduced wall thickness. A further highlight in the area of drinking water is the lead-free material CUPHIN, a silicon-bronze, which Wieland presents at a separate stand (Hall 6.0, Stand B44) shared with Diehl – with the amendment of the Drinking Water Regulations of 2013 in mind. Several well-known German manufacturers already have sanitary components made of CUPHIN in their range of products. This innovative material is not only used in taps, but is also suitable for many other products, from water meters to press fittings, which are also on exhibit. Another exhibit is the high-strength alloy K65, which is on display for the first time for refrigeration and high-pressure applications, for example with the coolant CO2.

Wieland takes the opportunity of the ISH fair not only as a platform for building-service applications, but also to present innovative technical solutions for the industrial sector. These include the latest development that rounds off the group of products centred on the high-strength alloy K65. This copper alloy is predestined for high-pressure applications. Besides this, Wieland exhibits the innovation cuproform – a quality of copper pipe for industrial applications, with highly deformable characteristics that simplify processes such as expanding, bending, compression or flanging. In many cases, for example in the manufacturing of connecting pipelines and fittings for heating, refrigeration and air-conditioning, the requirements on copper pipes far exceed their usual characteristics. In addition, Wieland presents cuproclean, a copper pipe for industrial applications with an exceptionally pure inner surface. And the latest addition to the solarclean family for vacuum-tube collectors, solarclean HP, is also available as of now.

Further information:

Wieland-Werke AG

Karin Maier, Press Relations

Graf-Arco-Straße 36 - 89079 Ulm

Telephone: +49 731-944-2663

Fax: +49 731-944-42663

karin.maier@wieland.de

www.wieland.de

Public Relations:

Press’n’Relations GmbH

Bruno Lukas

Magirusstraße 33 - 89077 Ulm

Telephone: +49 731-9628717

Fax: +49 731-9628797

blu@press-n-relations.de

www.press-n-relations.de

The Wieland Group is one of the world’s leading manufacturers of semi-finished and special products in copper or copper alloys: strips, sheets, pipes, rods, wires and profiles, and also sliding elements, ribbed pipes and heat exchangers. The products, made of more than 100 different copper materials, are used mainly in electronics and electrical engineering. Further important sectors supplied are the automotive industry, the building trade, cooling/air-conditioning and heating technology mechanical and apparatus engineering. Together with the customers, the company develops solutions for individual and industrial applications. The Wieland Group embraces more than 30 manufacturing companies, cutting centres and trading companies in Europe, Asia, South Africa and the USA. Wieland Werke AG owns four plants in Ulm, Velbert-Langenberg, Villingen-Schwenningen and Vöhringen. The branded copper pipes for Wieland building services are manufactured in Germany, at the Vöhringen (Bavaria) location. Development, production and marketing are certified according to DIN EN ISO 9001. In addition, the company has an accredited test and certification laboratory. The plants in Germany are certified according to the international environmental standard DIN EN ISO 14001; the largest plant, that in Vöhringen, is validated according to the European environmental standard EMAS. In the business year 2009/2010, the turnover of the Wieland Group was 2,653 million Euros. The exported portion was around 67 percent. Wieland employs some 6,500 people worldwide, more than 4,000 of them in Germany.