BAUR GmbH

Faster results with the Version 3.3 cable test van

Automated functions simplify cable measurements up to 80 kV

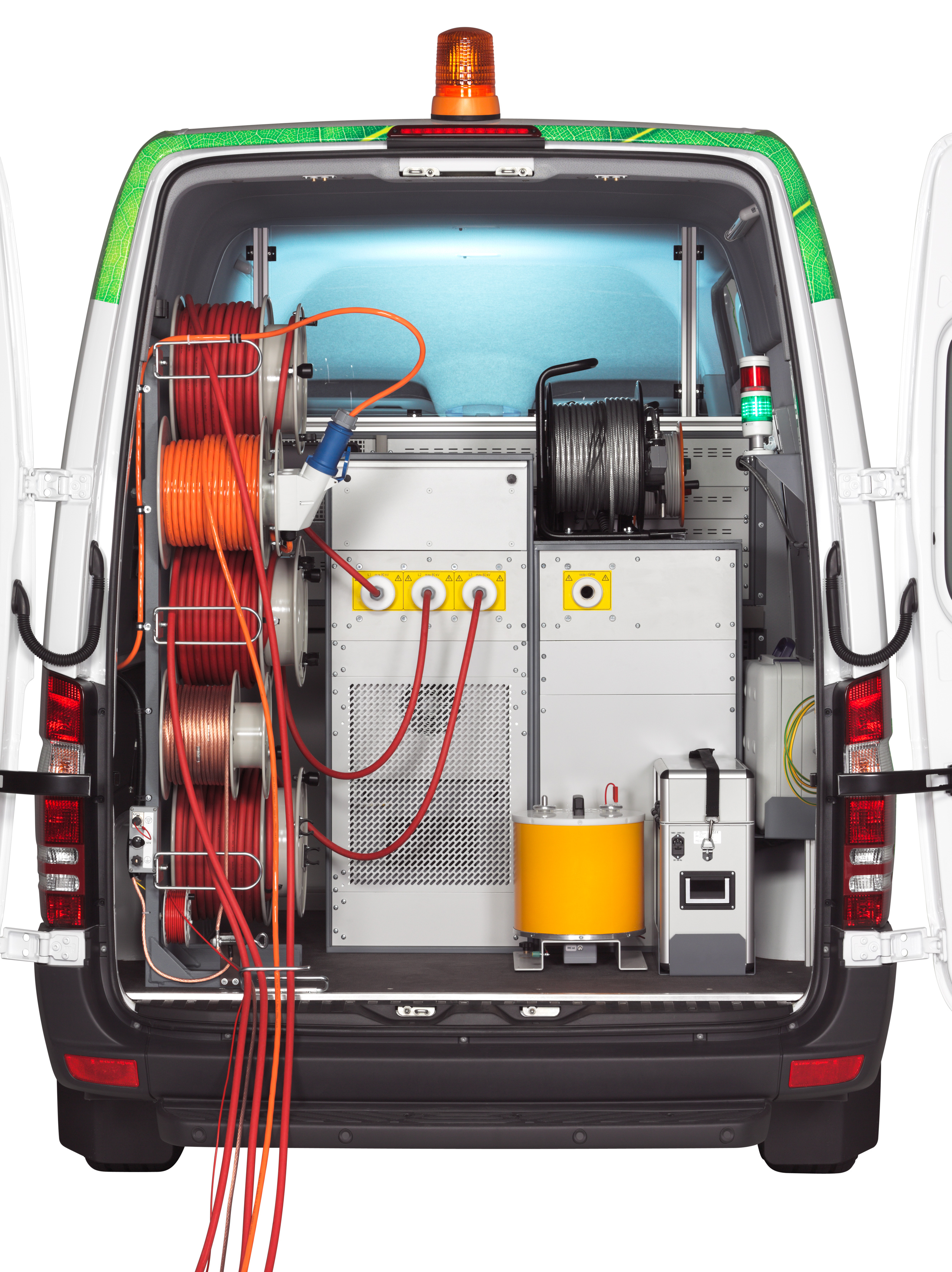

Less weight, more function – this was the guiding principle for developers for the latest improvements to the cable test van from BAUR Prüf- und Messtechnik GmbH. The result was that vehicle with 3.5 tonnes permitted total weight can now be delivered with equipment for automated cable testing, diagnostics and fault location for up to 80 kV DC or 57 kVrms. The weight reduction required to integrate the automated functions in a vehicle of this class is achieved by technologies such as the new, encapsulated GPW 80 device selector switch, which is now electric rather than hydraulic.

The new BAUR system software version 3.3 also enables users to run many measurements such as cable testing, diagnostics and partial discharge measurement or fault location automatically and have the results analysed. Moreover, there are new functions such as phase resolution and frequency filters for partial discharge measurement. The program interface is available in 21 languages, makes operations easier and saves time. To enable more effective use of time, BAUR cable test vans can also perform conventional cable testing and diagnostics concurrently, because the same voltage source is used for both.

Faster results

Automation is used to speed up calibration and the test sequence during partial discharge measurement, for example. The software identifies unusual values independently, simplifying evaluation. For measurements which are difficult to analyse, the operator can apply various frequency filters to the result manually to suppress interfering signals. Moreover, BAUR software enables the phasing of the partial discharges to be analysed.

The new "easy" mode enables faults to be found faster. It automatically controls resistance measurements as well as echometric and SIM/MIM measurements. In 98% of cases, this combination of methods succeeds in locating the fault. Thus users only need the "expert" mode in rare cases where faults must be identified in complex grids using difference, surge current and decay methods. The new software also provides a mode for locating joints, the results of which can be stored in the cable database – important for correctly representing the existing grid.

Simplified condition evaluation for cable stock

It's now also easier to evaluate cable systems. The dissipation factor measurement technology integrated in the cable test van enables the ageing condition of insulation in XLPE and paper insulated mass-impregnated cables to be investigated. BAUR system software indicates a classification directly based on measured tan delta values, so cable lines with problems can be identified quickly. Instead of using default classification criteria, customers can specify their own limit values.

An USB interface can be used to transfer all the measurement results from the system software and/or cable database content to an external computer so they are available for further analyses of mains operation and maintenance, such as trend analyses and a record of the cable history in the operating resources database.

Picture: BAUR_KMW_6.jpg

The new 3.5 tonne BAUR cable test van also enables automated cable testing, diagnostics and fault location up to 80 kV, and provides a wealth of new functions with version 3.3 of the BAUR system software.

Picture: BAUR_KMW_Bedienraum.jpg

High-pass, low-pass and bandpass filters enable interference to be removed from the partial discharge measurement results display, which simplifies the analysis.

Picture: BAUR_TE-Filter.jpg

Improved interior design and and BAUR system software version 3.3 to make the operation easier than ever with a variety of new automation and analysis functions. This makes measurement, testing and fault location faster than ever as well.

More information / Press contact:

BAUR Prüf- und Messtechnik GmbH

Sonja A. Ostermann

Raiffeisenstrasse 8 – 6832 Sulz (Austria)

Phone: +43 (0)5522 4941-55

Fax: +43 (0)5522 4941-8055

www.baur.at

Press’n’Relations II GmbH

Ralf Dunker

Guntherstrasse 19 – 80639 Munich (Germany)

Phone: +49(0)89 17999275

Fax: +49(0)89 17999289