Framework agreement concluded: Nexans DuoTrack® cable solution is the new standard for regional railway cabling

Plans to lay up to 1,500 km over the next three years

Deutsche Bahn AG has signed a framework agreement for the production, delivery and assembly of the DuoTrack® cable solution with the consortium (ARGE) of the same name. The consortium, consisting of railway transportation technology experts Contec GmbH, Ötzingen-Sainerholz, communications specialists telent GmbH, Backnang, and the pioneering Nexans Deutschland GmbH, Moenchengladbach, will equip up to 1,500 kilometres of non-electrified regional railway track with the all-in-one system solution over the next three years. This represents a maximum order volume of 60 million euros.

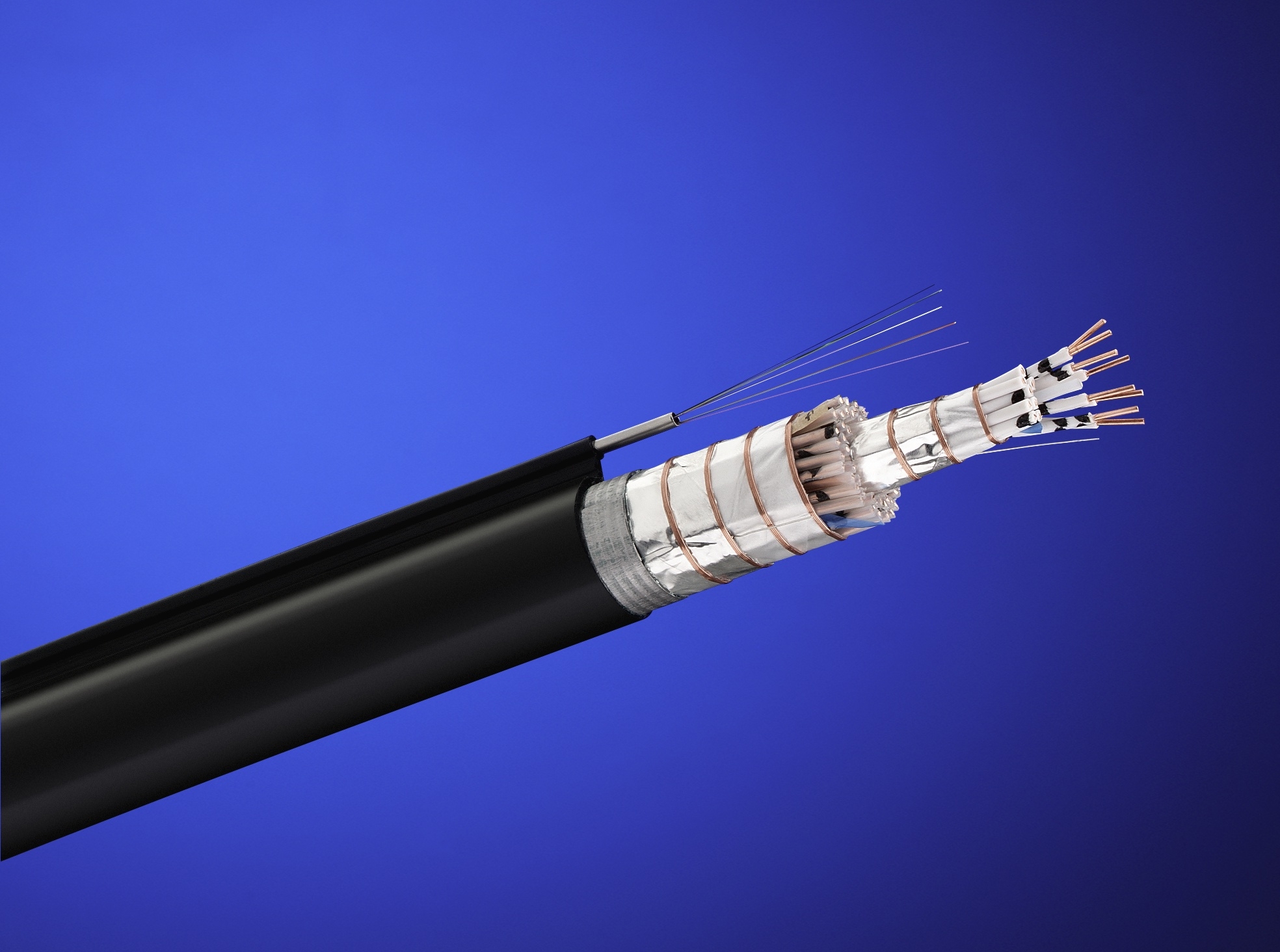

The DuoTrack® cable was developed for assembly on the rail base and combines a specially designed, multi-wire copper cable with a fibre-optic cable in a joint arrangement. This provides sufficient capacity for all relevant regional railway services. Parallel operation of all necessary control and security technology services using the cable has been tested and approved: Nexans DuoTrack® has received type approval from the German Federal Railway Authority and has been tried and tested in selected regional network projects e.g. in the Odenwald forest, near Gifhorn as well as on the tracks Muenster-Hemfeld and Hagen- Dieringshausen. To begin with, the regional railway routes Neustadt - Bad Schandau (25 km), the Highland Rail (26 km) and tracks in the Harz-Weser-Net are to be equipped with the cable.

The framework agreement makes the DuoTrack® cable the standard solution for cabling nonelectrical regional routes, which do not already have a concrete trough as a cable routing system. Juergen Rueth, Head of Telecommunications Sales and Marketing at Nexans Deutschland, explains why. "Besides the technical advantages of being able to transmit the entire range of services all-in-one using a single cable, further benefits of DuoTrack® include the low installation costs and the short implementation phases. It takes 16 weeks to equip 20 kilometres of railway line with conventional cables inclusive concrete trough. We can do a comparable DuoTrack® solution in four weeks!”

The time benefits and the concomitant cost reduction result from the fact that the cable is attached to the rail – thus eliminating the need to construct troughs – and the coordinated DuoTrack® system. The Duotrack® attachment clamps, the assembly and testing technology as well as a special cable-laying vehicle with the capacity to lay several kilometres per day were developed by consortium member Contec in conjunction with Nexans. A cable joint system produced by Nexans completes the solution.

Pictures:

DuoTrack® is an innovative all-in-one system solution for quick, cost-effective and long-term railway cabling for non-electrified regional railway lines. 1: the DuoTrack® cable; 2: the laid cable; 3: laying the cable using the special vehicle; 4: attaching the cable with special holding clamps produced by Contec.

About Nexans Germany

Nexans is one of the leading cable manufacturers in Europe. The company is offering an extensive range of high performance cables, systems, and components for the telecommunications and energy sectors, rounded off by superconducting materials and components, Cryoflex transfer systems and special machinery for the cable industry. Producing at manufacturing plants with 7.400 employees in Germany and abroad, the sales in 2007 amounts to approx. 958 Mio Euro. The full integration into the Nexans Group Nexans Germany also benefits from excellent opportunities to use the available synergies in all corporate fields, which not only applies to worldwide projects but also to research and development, the exchange of know how, and to other areas. More information on www.nexans.de

Further information / press contact

Nexans Deutschland GmbH

Jutta van Bühl

Bonnenbroicher Strasse 2-14

D-41238 Moenchengladbach

Telephone: +49 (0)2166 27-2495

Fax: +49 (0)2166 27-2497

Internet: www.nexans.de

Press’n’Relations II GmbH

Ralf Dunker

Guntherstraße 19

D-80639 Munich

Telephone: +49 (0)89 17999275

Fax: +49 (0)89 17999289

Internet: www.press-n-relations.de