News of GEA Air Treatment Services from the Trade Fair SHK 2010, Essen (Germany)

GEA MATRIX – and there you have effective control of room-air quality / Connection kit enables split HVAC combinations of GEA and Mitsubishi units

- GEA MATRIX – and there you have effective control of room-air quality -

The GEA MATRIX 400x control system for ventilation units with outdoor-air connection, as well as the GEA MATRIX 4700 for compact and central air-handling units, will be provided – beginning with Version 2.70 – with standard air-quality control functions. This feature is pre-configured at the manufacturer’s plant and is simply activated when the sensor is connected. The operator panel with display will show the current CO2 value, measured in ppm (parts per million). Such an air-quality sensor (e.g., for measurement of CO2 or gas mixtures) makes it possible to continuously adjust the air flow of the connected ventilation units in accordance with room-air quality. The result is reduced energy consumption with high room-comfort levels at the same time.

With the factory setting, the air flap is opened to 100 % when the CO2 share in the room air increases. Then the fan speed is increased. This procedure can be modified, however: with the aid of GEA MATRIX.PC service software, this setting can be changed to enable the air flow to be increased by raising the motor speed and/or by regulating the air flap.

Picture GEA_MATRIX_Kurve01.jpg:

The new GEA MATRIX control system matches the air flow to the measured values reported by a CO2 or mixed-gas sensor.

Picture GEA_Matrix4700.jpg:

The GEA MATRIX 400x control system for ventilation units with outdoor-air connection, as well as the GEA MATRIX 4700 (see image) for compact and central air-handling units, include control functions for assuring air quality.

-------------------------------------

- Connection kit enables split HVAC combinations of GEA and Mitsubishi units -

The connection kit PACIF0xxB-E allows operation of a large number of GEA heat-exchanger types with Mitsubishi P-Series units. For example, interfacing Mitsubishi Electric outdoor heat pumps is now possible without their heat-pump system Ecodan. It is especially in the restoration of old buildings that such a solution can be most effective, since it enables further use of existing units such as storage and pumps. Here, the outdoor units are simply integrated into existing systems via the interfaces of the connection kit (IF011B-E or PAC-IF021B-E).

With this connection kit, heat pumps or split outdoor units can be operated in combination with ventilation systems, air curtains, and many more systems. The kit consists of a controller box with a special circuit board with microprocessor control, as well as two temperature sensors. The controller box is connected to the outdoor unit via a control interface, and performance setpoints can be managed on eight levels, from 30 to 100 %, by means of a great number of external signals. Likewise possible are settings such as heating and cooling modes and compressor shutdowns.

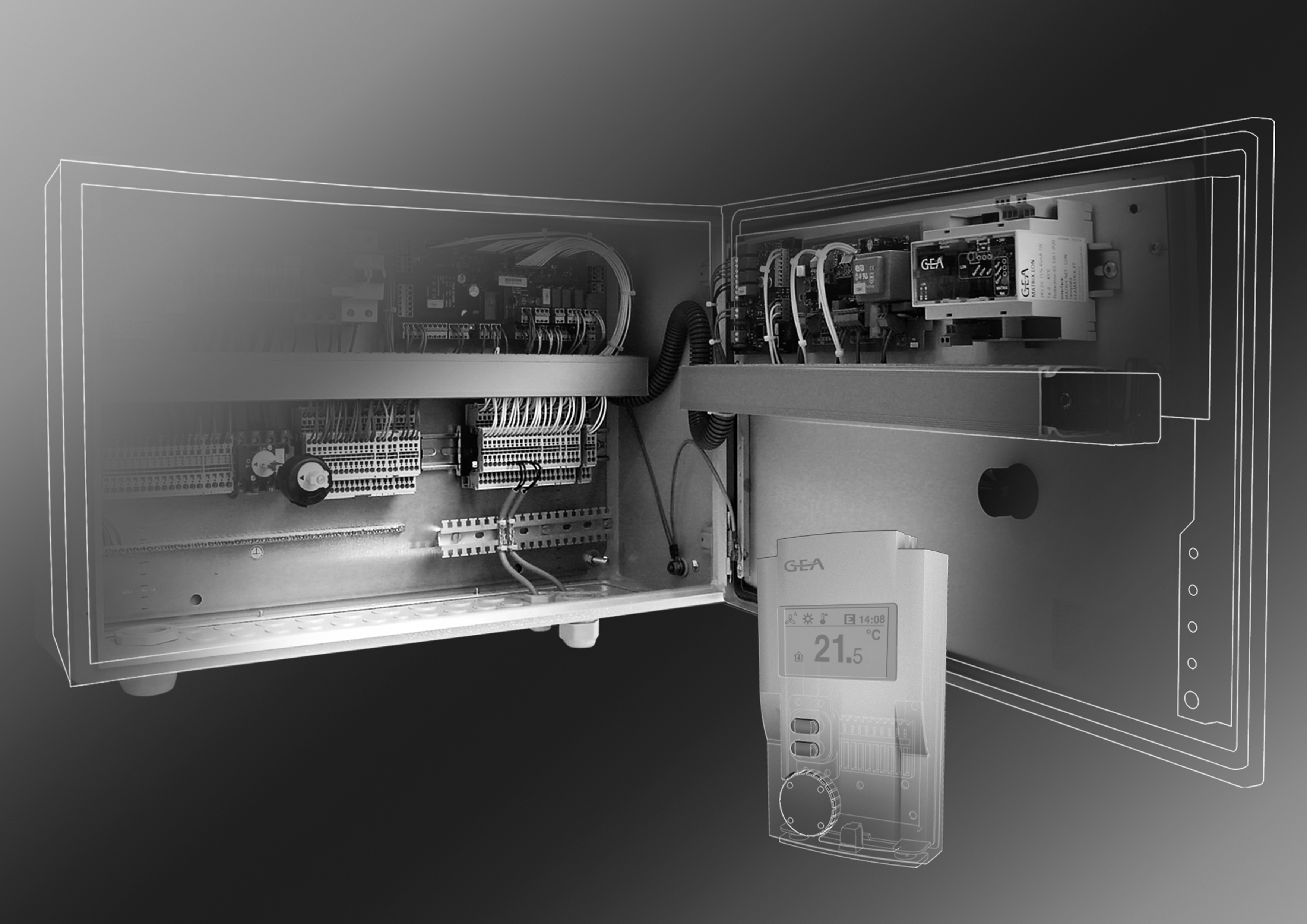

Picture Mr.Slim-System_bw.jpg:

Use of the connection kit with a ventilation system

-------------------------------------

Press Relations and Public Affairs:

GEA Air Treatment Services GmbH – Ms. Annette Wille

Suedstrasse 48 – 44625 Herne, Germany

Tel.: +49 (0)2325 468 206 - Fax: +49 (0)2325 468 401

www.gea-airtreatment.com

Press’n’Relations II GmbH – Uwe Taeger

Guntherstrasse 19 - 80639 Munich, Germany

Tel.: +49 (0)89 179 992 77 - Fax: +49 (0)89 179 992 89

About GEA

GEA Group Aktiengesellschaft is one of the largest systems providers in the food and beverages industries, and in energy production. Group sales in 2008 were approximately 5.2 billion euros. As an internationally active technological enterprise, GEA Group has concentrated on process engineering and components for demanding production processes in a wide range of end-user markets. The Group generates around 70 % of its sales in long-term growth industries for food, beverages, and energy. As of 30 September 2009 the Group employed more than 20,000 staff, who are accessible to customers in 50 countries. In 90% of its business areas, GEA Group is among the leading market and technology companies. GEA group is listed on the German MDAX stock index (G1A, WKN 660200).